Research and Development

Research and Development

The production phases take place almost entirely inside the plant and this guarantees high levels of privacy and reliability as requested by a prestigious and illustrious clientele. Over the years the company always invested in research, in new technologies and in staff training in order to offer the best service with a very high product quality, keeping at the same time competitive prices.

The production phases take place almost entirely inside the plant and this guarantees high levels of privacy and reliability as requested by a prestigious and illustrious clientele. Over the years the company always invested in research, in new technologies and in staff training in order to offer the best service with a very high product quality, keeping at the same time competitive prices.

Continuous innovation

Continuous innovation

The company is in a process of continuous development, ready to recognize the latest fashion trends and to materialize it in high quality Made in Italy products. The image of Magonio is the one of an harmonious group of people, ready to roll up their sleeves and deal with new challenges, in order to represent the honest Italy that works, that wants to win the global challenge.

The company is in a process of continuous development, ready to recognize the latest fashion trends and to materialize it in high quality Made in Italy products. The image of Magonio is the one of an harmonious group of people, ready to roll up their sleeves and deal with new challenges, in order to represent the honest Italy that works, that wants to win the global challenge.

Phases of production

Phases of production

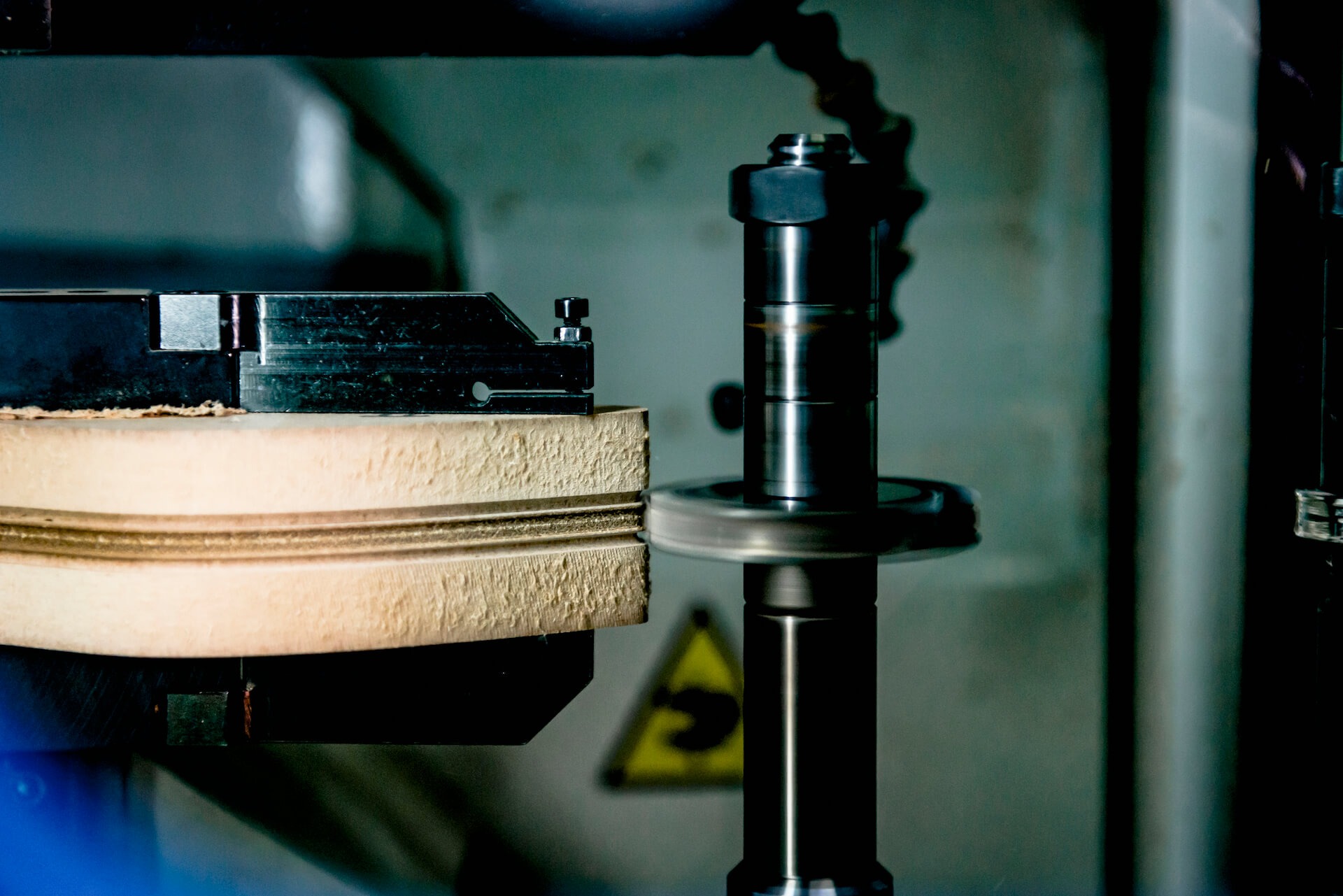

Soles, from the beginning to the end of the production process, pass through many different phases: cutting, equalization , branding, milling, painting, stamping, curving the edge, Jordanatura, brushing, packaging and others. With regard to monobloc soles or soles with injections, some phases must be added: pantograph, injection, application of different elements and the finishing touch.

Soles, from the beginning to the end of the production process, pass through many different phases: cutting, equalization , branding, milling, painting, stamping, curving the edge, Jordanatura, brushing, packaging and others. With regard to monobloc soles or soles with injections, some phases must be added: pantograph, injection, application of different elements and the finishing touch.